Clothing needs not one but multiple lives.

Jordon MacInnis - Circular Economics

High tech design.

Given our experience in design and manufacturing, combined with our location in the creative hub of Brighton with staff who are Fashion & Textile graduates, we are at the forefront of commercially focused upcycling. With funding from Innovate UK and a partnership with the University of Brighton, we have developed multiple upcycled business models that use CLO, the 3D Fashion design garment visualization software, to significantly reduce development time and reduce costs.

Development & manufacturing.

Our CLO developing upcycled products can be reproduced worldwide. We design and produce samples in our Upcycling Lab in Brighton, England. We have our own UK manufacturing facility for smaller volumes and have a larger capacity in Turkey. Our network of upcycling companies covers the UK and Europe and has expanded into the US in order to give brands a consistency across territories, with a simultaneous objective to drive employment in this new circular industry.

You can shape the future.

Even with the best will in the world there will come a point where a garment can no longer be restored into a valuable product. The options then are either to recycle, which is energy intensive, or to upcycle where instead value can still be captured from the textiles. Upcycling is a new and challenging area that requires collaboration between brands and individuals in order to make this section of the market, not only viable but also desirable.

Here’s how.

Design.

Upcycling is the ultimate in creativity requiring an open mindset, a willingness to push the boundaries and the ability to answer many questions. How can the textiles be repurposed? What will the new garment set out to achieve? How can desirability be created? What innovations can be derived from the project?

Create.

By answering the questions posed from the design analysis we can create the product in our Upcycling Lab with sorting, grading and cutting all done onsite. This provides an opportunity for experimentation and Live analysis, adapting the new product to an ever questioning design brief.

Inform.

The upcycling process is about design and creativity but most importantly about learning. Each project helps inform how the design process can be improved. Not just for upcycled clothing but also new products. Ones that are designed for upcycling at the end of their life so they are better suited to the circular economy.

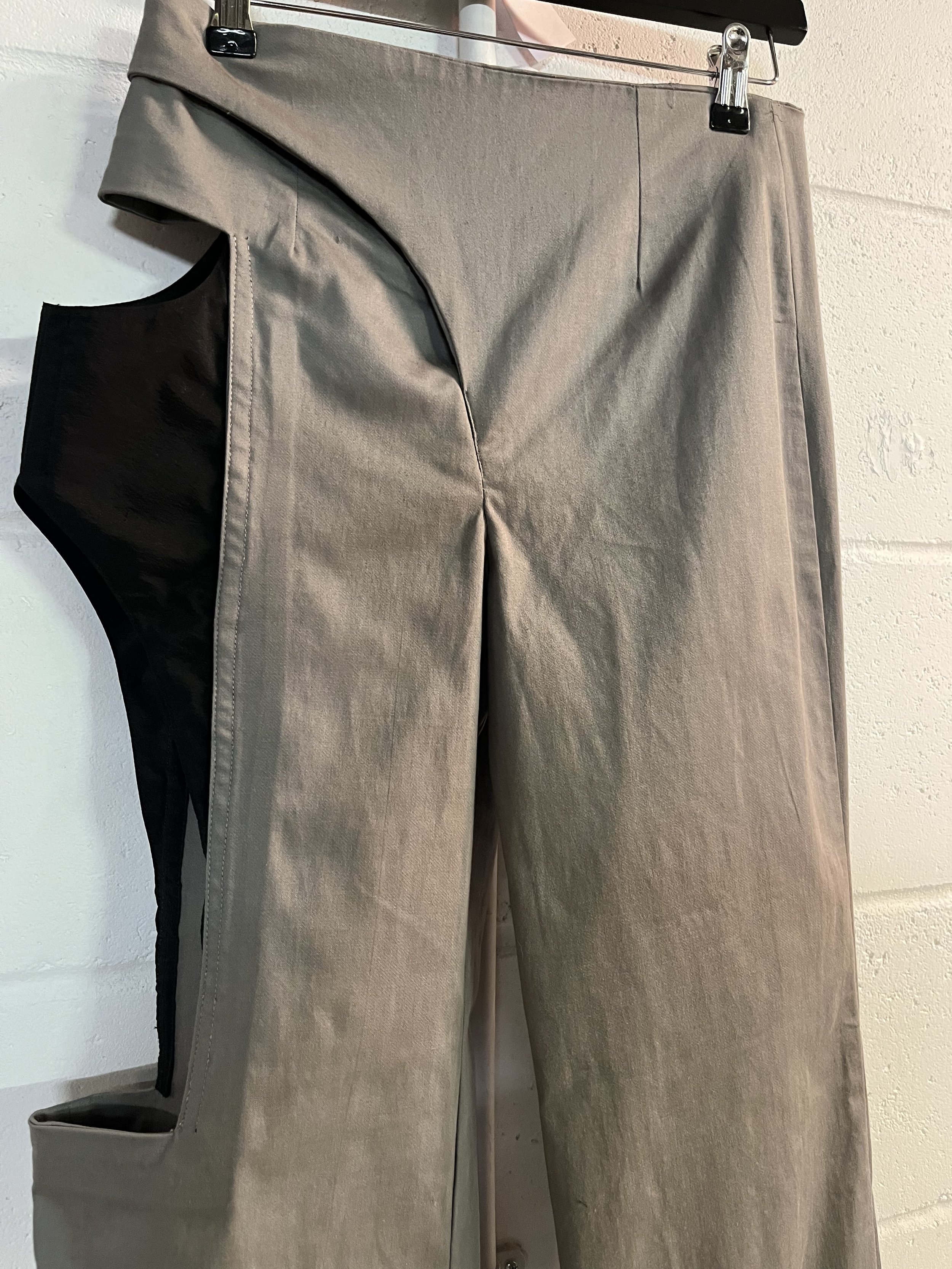

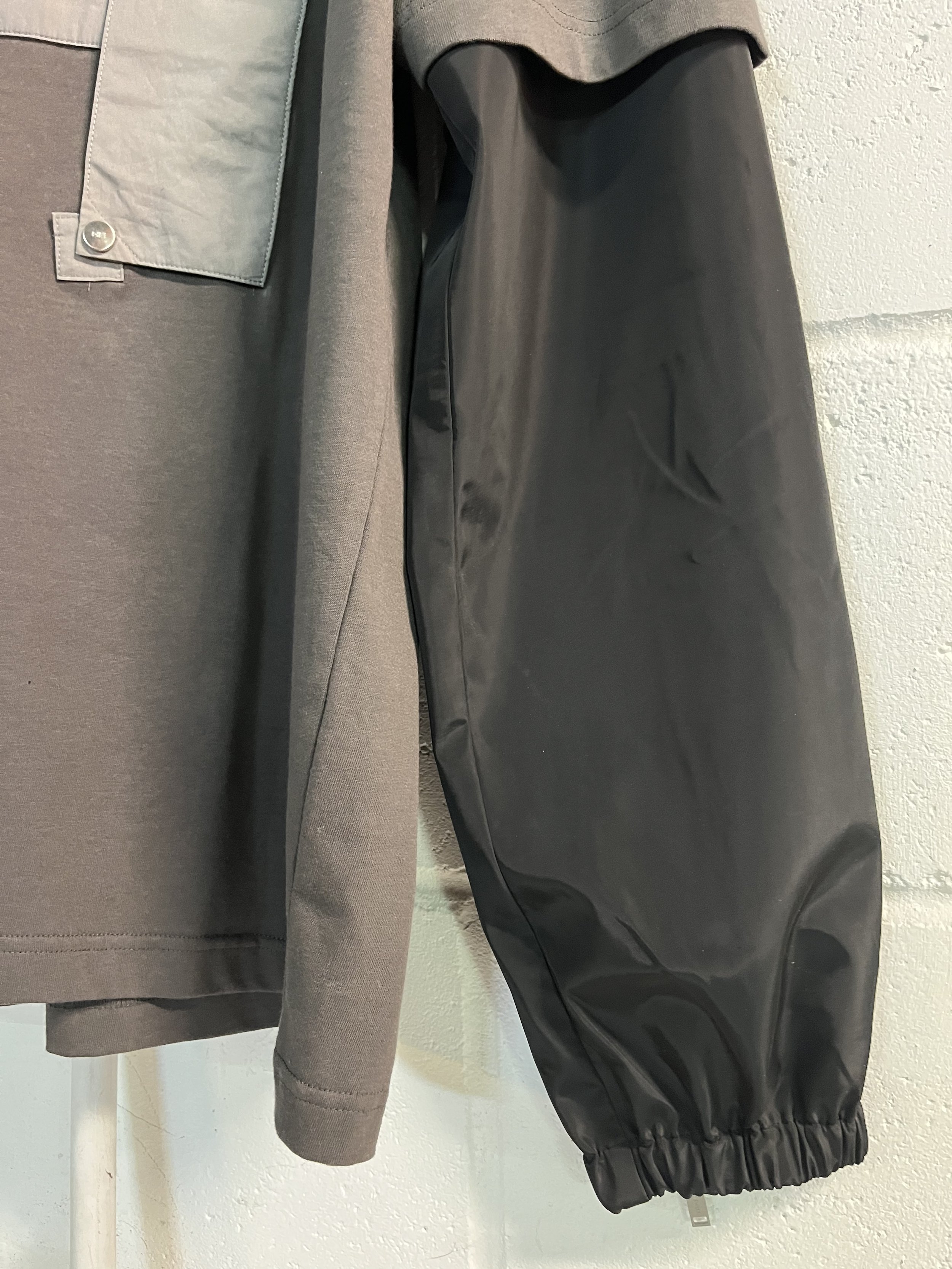

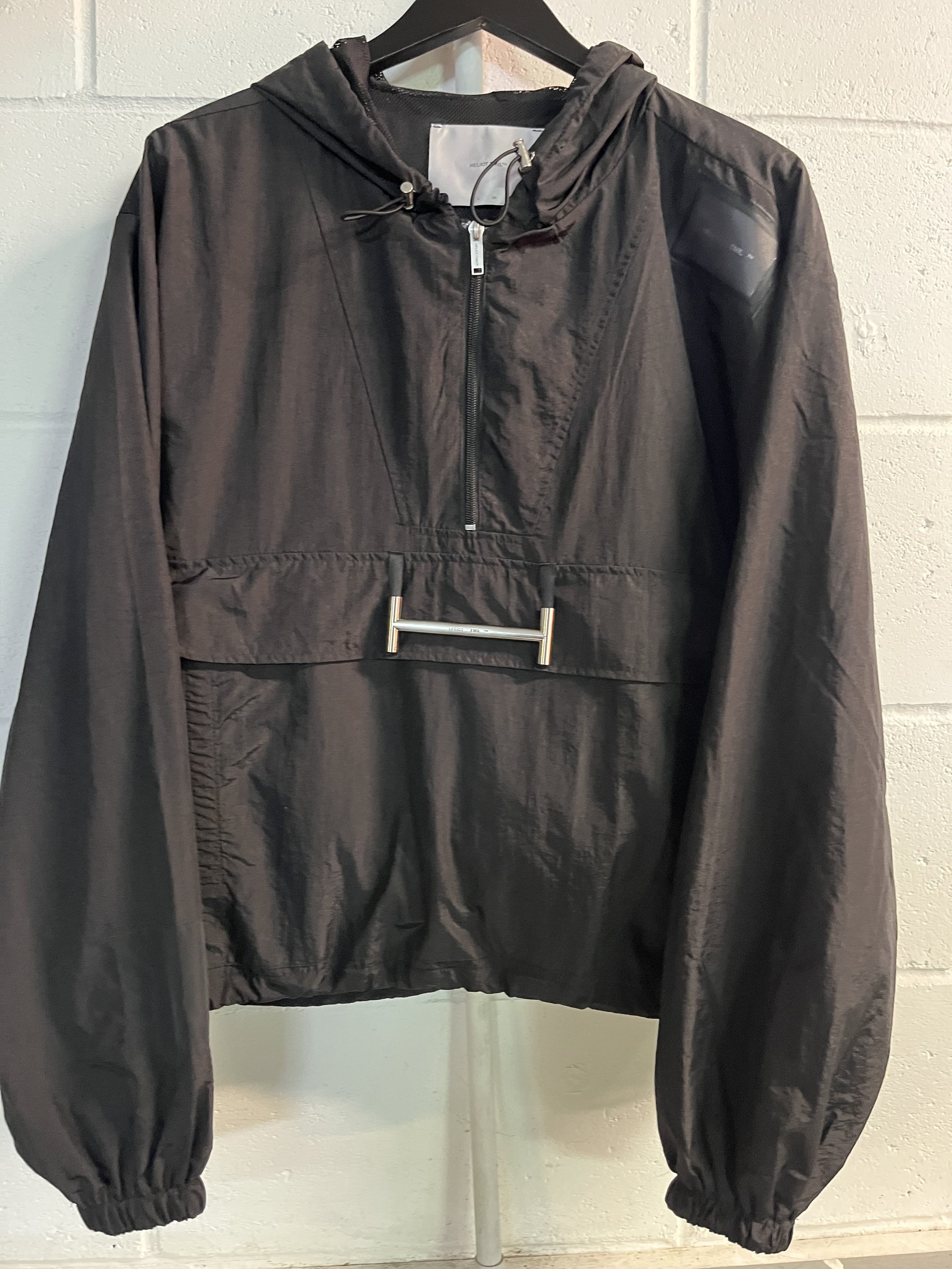

Fashion to fitness.

We’ve upcycled for high fashion brands such as Heliot Emil to fitness brands such as Lululemon. Here is a selection of some of our work.

Osprey Upcycled.

We work with Osprey to take their end of life backpacks and develop them into commercially viable products with an aesthetic, style and functionality that mirrors their brand ethos and functionality.

Taking it back to basics.

Before we design any new products we completely disassemble the backpacks, identifying parts that will be best used in templated products we have created. We also build stock of fabrics and trims that can be used further down the line in other products. The aim is to recycle as little as possible and to make use of what is available.